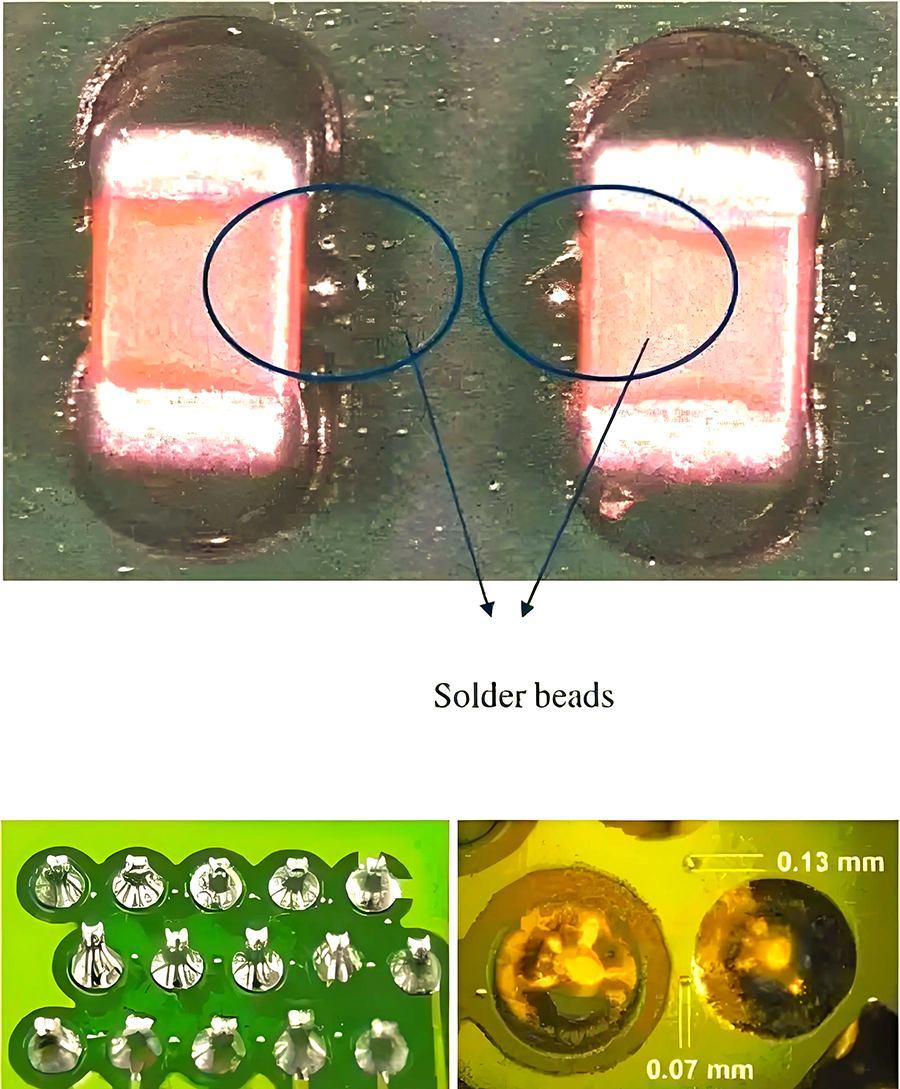

There are many problems in the production process of PCBA, among which short circuit failure caused by tin beads is always hard to guard against. Zhongshan Lewei Electronic Technology Co., Ltd. has many ways to solve this problem, including improvement in production, process improvement, and optimization from the source of design.

(1) Optimize the temperature curve setting of the reflow oven. The temperature rise slope should not be too fast in the preheating stage. The temperature rise slope setting should be less than 2℃/second, especially for complex server motherboards with too dense components, to ensure that the components are preheated evenly and smoothly.

(2) For LED packaged components, control the mounting pressure during machine mounting.

(3) The solder paste should be strictly kept in the specification for more than 4 hours of warming time before printing, and stirred for 3-5 minutes during use.

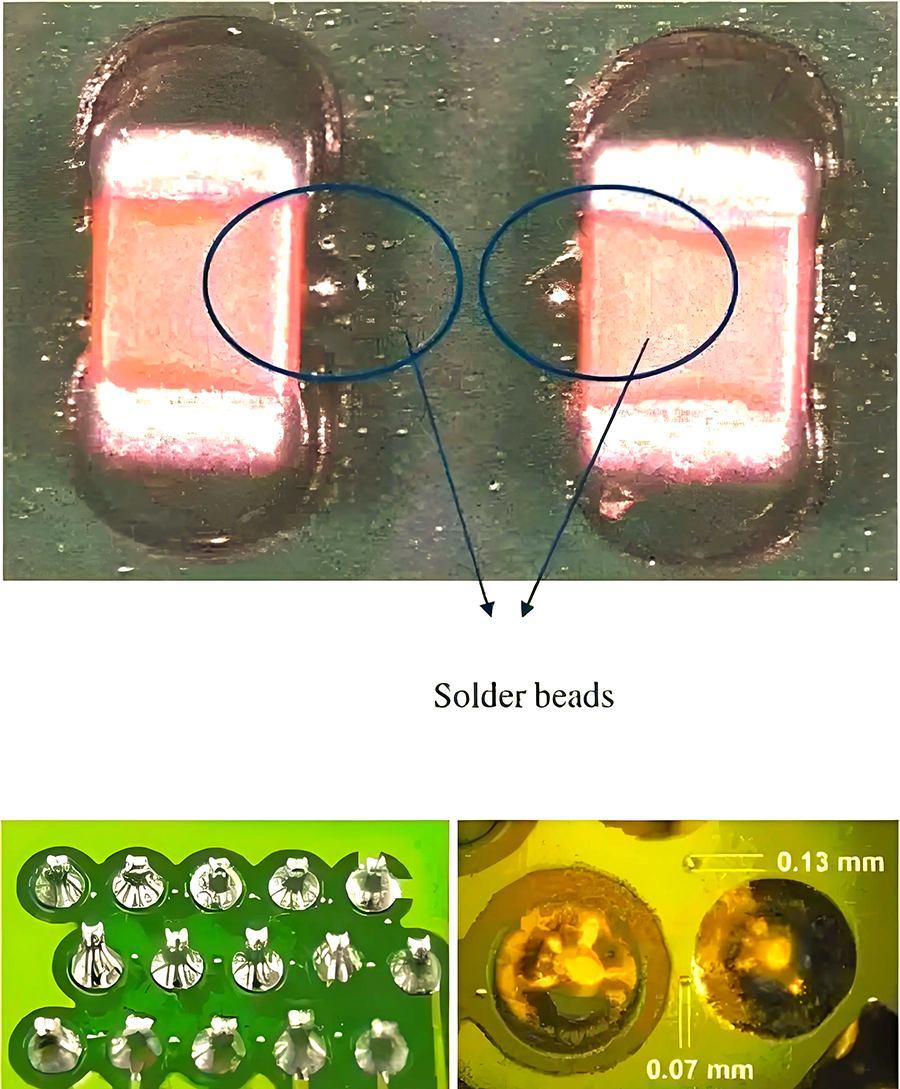

(4) The shape and size of the opening of the steel mesh should be optimized according to the bad phenomenon of the solder joints. It is very important to optimize the tinning amount based on the actual problems and continuously summarize the experience. It is very important to standardize the opening design of the steel mesh, otherwise it will directly affect the production pass rate. )

The above methods can solve the problem of tin beads generated during production due to pad mismatch.